Valiadis Hellenic Motors SA

18, Gr. Lambraki Str., 141 23 Likovrisi, Greece

Tel.: +30 2102817217

Fax: +30 2102814277

www.valiadis.gr

valiadis@valiadis.gr

» Support / Repairs

|

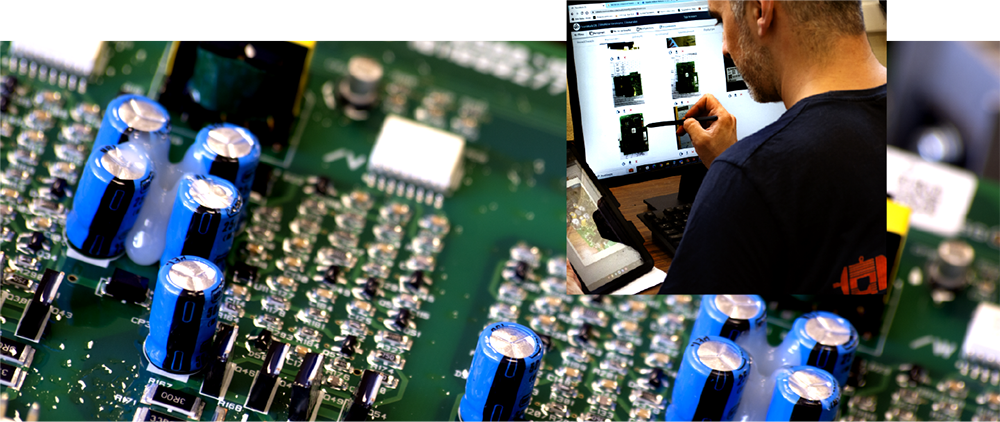

Support / Repairs

English

|

|

Support and RepairsFor high voltage, low voltage and DC motors

Our Company has an organized repair unit, the unique in Greece certified with ISO 9001. We undertake the repair of any kind of motors (AC and DC). We have also developed a repair unit specialized in High Voltage Motors. In this respect, expertise engineers of our Company attended relevant seminars abroad. The HV Electric Motors repaired in our factory, are many years in operation with excellent results.

Works

ISO 9001 certified, highly qualified specialists:

All High Voltage AC stators repaired by our Company undergo strictly the following tests according to VDE 0530 and IEC-34 specifications:

Certifications

Digital

And get it done.

|